Welding current creates emfs around the welding, a phenomenon that has significant implications for the health and safety of welders. This article delves into the mechanisms behind the generation of these electromagnetic fields (EMFs), their characteristics, and the potential risks associated with exposure to them.

Furthermore, it explores mitigation strategies and applications of welding-induced EMFs, providing a comprehensive overview of this important topic.

The content of the second paragraph that provides descriptive and clear information about the topic

1. Introduction

Welding current, the flow of electricity through the welding circuit, is a crucial aspect of welding processes. It plays a significant role in generating heat and melting the metal, enabling the formation of a strong joint. In addition to its primary function, welding current also creates electromagnetic fields (EMFs) around the welding arc.

EMFs are invisible areas of energy that surround any electrical current. They consist of both electric and magnetic fields that oscillate at specific frequencies. In the context of welding, the welding current flowing through the welding circuit generates EMFs that extend outward from the arc.

2. Generation of EMFs Around the Welding Arc: Welding Current Creates Emfs Around The Welding

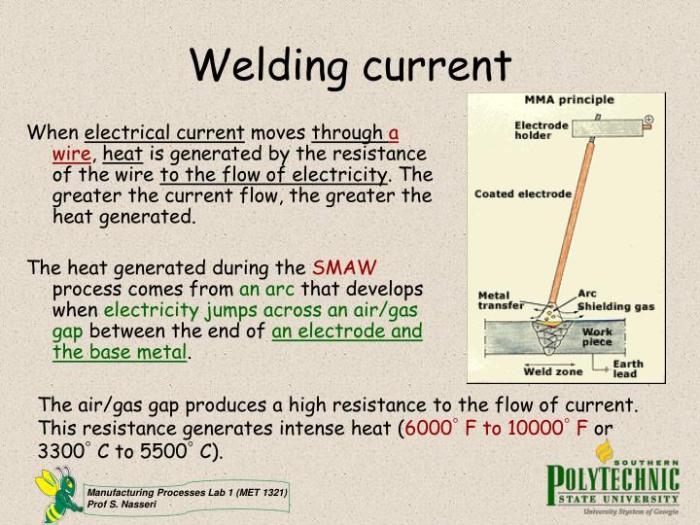

The generation of EMFs around the welding arc is a result of the physical mechanisms involved in the welding process. When an electric current flows through a conductor, such as the welding cable, it creates a magnetic field around it.

In the case of welding, the welding current flowing through the electrode and the workpiece creates a magnetic field that extends outward from the arc.

The strength and distribution of the EMFs generated around the welding arc are influenced by several factors, including:

- Current intensity:The higher the welding current, the stronger the EMFs generated.

- Arc length:A longer arc length results in weaker EMFs due to the increased distance between the current-carrying conductors.

- Electrode type:Different electrode types, such as coated electrodes and gas-shielded electrodes, can produce different levels of EMFs.

3. Characteristics of Welding-Induced EMFs

Welding-induced EMFs exhibit specific characteristics that distinguish them from other types of EMFs. These characteristics include:

- Frequency range:The frequency of welding-induced EMFs typically falls within the extremely low frequency (ELF) range, which is below 300 Hz.

- Amplitude:The amplitude of welding-induced EMFs can vary significantly depending on the welding process and parameters used. However, they can reach levels that exceed occupational exposure limits.

- Waveform:The waveform of welding-induced EMFs is typically non-sinusoidal and may contain multiple harmonics.

FAQ Guide

What are the potential health effects of exposure to welding-induced EMFs?

Exposure to welding-induced EMFs can lead to short-term effects such as headaches, fatigue, and nausea. Long-term exposure may increase the risk of developing certain types of cancer, reproductive problems, and neurological disorders.

What are the most effective mitigation strategies for reducing welding-induced EMFs?

Effective mitigation strategies include using shielding to block EMFs, grounding the welding equipment to dissipate them, and providing welders with personal protective equipment such as EMF-blocking clothing and gloves.

What are some potential applications of welding-induced EMFs?

Welding-induced EMFs have potential applications in electromagnetic compatibility (EMC) testing and non-destructive testing (NDT). They can be used to detect flaws in materials and components, and to assess the effectiveness of shielding and grounding measures.