Precision Machining Technology 3rd Edition unveils a comprehensive exploration of the intricacies of precision machining, inviting readers to delve into the world of precision and accuracy. This updated edition delves deeper into the latest advancements and applications, providing a comprehensive understanding of the field.

As the world of manufacturing evolves, precision machining emerges as a cornerstone of innovation, shaping industries from aerospace to medical technology. This book serves as an indispensable guide for engineers, technicians, and students seeking to master the art of precision machining.

Overview of Precision Machining Technology 3rd Edition

Precision Machining Technology 3rd Edition is a comprehensive textbook that provides a detailed overview of the latest advancements and techniques in the field of precision machining. It covers a wide range of topics, including precision machining processes, machine tools and equipment, cutting tools and materials, measurement and inspection, quality control, and applications of precision machining technology.

The book is written by a team of experts with extensive experience in the field, and it is designed to be a valuable resource for students, engineers, and technicians who are involved in precision machining.

The third edition of Precision Machining Technology has been updated to include the latest information on precision machining processes, machine tools, and cutting tools. It also includes new chapters on quality control and applications of precision machining technology.

Precision Machining Processes: Precision Machining Technology 3rd Edition

Precision machining processes are used to create parts with high levels of accuracy and precision. These processes can be used to produce parts for a variety of industries, including aerospace, medical, and automotive.

- Turningis a process in which a cutting tool is used to remove material from a rotating workpiece.

- Millingis a process in which a cutting tool is used to remove material from a stationary workpiece.

- Grindingis a process in which a rotating abrasive wheel is used to remove material from a workpiece.

- Electrical Discharge Machining (EDM)is a process in which an electrical spark is used to remove material from a workpiece.

- Laser Cuttingis a process in which a laser is used to cut material.

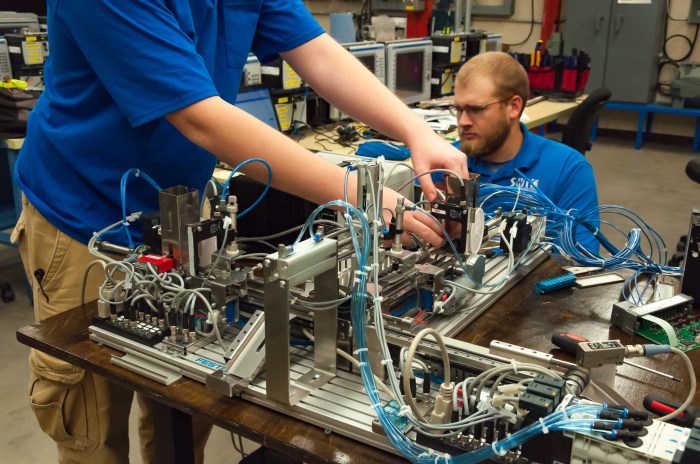

Machine Tools and Equipment

Machine tools are used to perform precision machining processes. These machines can be either manually or computer-controlled.

- Lathesare used for turning operations.

- Milling machinesare used for milling operations.

- Grindersare used for grinding operations.

- EDM machinesare used for EDM operations.

- Laser cutting machinesare used for laser cutting operations.

Cutting Tools and Materials

Cutting tools are used to remove material from a workpiece. These tools can be made from a variety of materials, including high-speed steel, carbide, and diamond.

The choice of cutting tool material depends on the type of material being machined, the desired surface finish, and the required accuracy and precision.

FAQ Insights

What are the key benefits of using precision machining technology?

Precision machining technology offers numerous benefits, including improved product quality, increased efficiency, reduced production costs, and enhanced competitiveness in the global marketplace.

What are the different types of precision machining processes?

Precision machining encompasses various processes, such as turning, milling, drilling, grinding, and electrical discharge machining (EDM), each with its unique capabilities and applications.

How can I ensure quality control in precision machining?

Quality control in precision machining involves implementing rigorous inspection and testing procedures, utilizing advanced measuring equipment, and adhering to industry standards and best practices.