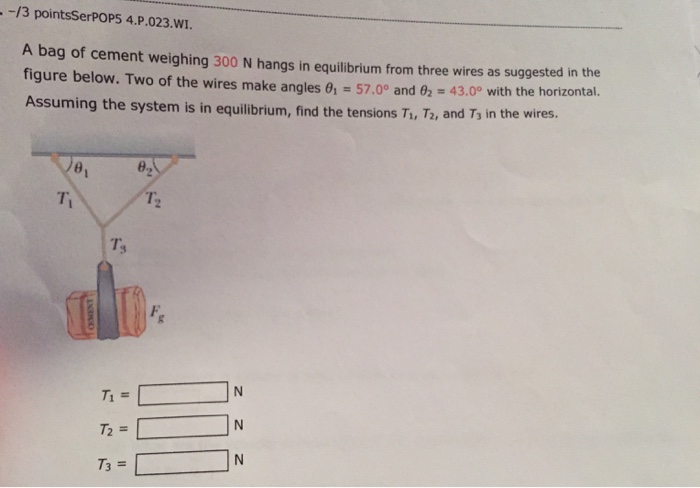

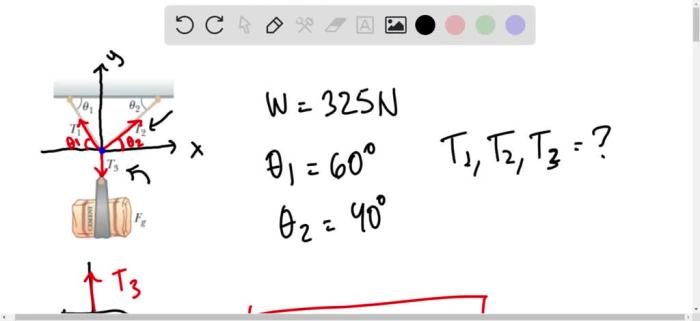

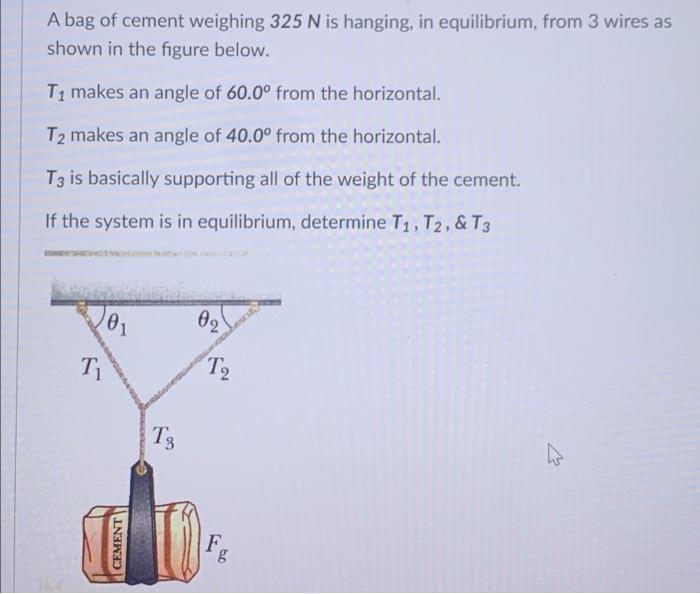

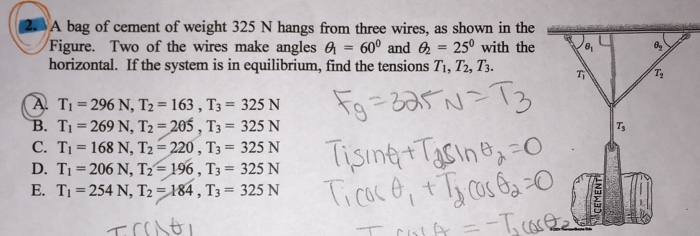

A bag of cement weighing 325 n – Embarking on a journey into the realm of construction materials, let’s delve into the intricacies of a 325 N bag of cement. This exploration promises to shed light on its composition, applications, and environmental implications.

Cement, a ubiquitous substance in the construction industry, is renowned for its ability to bind materials together, forming the foundation of countless structures.

Definition and Description of Cement

Cement is a powdery substance that, when mixed with water, forms a paste that hardens over time. It is used as a binder in construction materials such as concrete and mortar. Cement is made from a mixture of limestone, clay, and other materials that are heated in a kiln to produce a clinker.

The clinker is then ground into a powder and mixed with other ingredients to create different types of cement.

Composition and Properties of Cement

The main components of cement are calcium oxide (CaO), silicon dioxide (SiO2), aluminum oxide (Al2O3), and iron oxide (Fe2O3). These compounds react with water to form a hydrated cement paste that hardens over time. The properties of cement include strength, durability, and resistance to fire and water.

Types of Cement

There are many different types of cement available, each with its own unique properties. Some of the most common types of cement include:

- Portland cement is the most common type of cement used in construction. It is made from a mixture of limestone, clay, and other materials that are heated in a kiln to produce a clinker. The clinker is then ground into a powder and mixed with other ingredients to create Portland cement.

- Masonry cement is a type of cement that is used in the construction of masonry structures, such as brick and stone walls. It is made from a mixture of Portland cement and other ingredients that make it more workable and easier to use in masonry applications.

- White cement is a type of cement that is made from a mixture of white limestone and other materials. It is used in applications where a white or light-colored finish is desired.

Weight of Cement

The weight of the bag of cement is a crucial factor in determining its handling and storage requirements. It is essential to understand how the weight is measured and expressed in different units.

In this section, we will delve into the weight of the cement, exploring the conversion between Newtons (N) and kilograms (kg) and calculating the mass of the cement in the bag.

Conversion of Units

The weight of the bag of cement is given as 325 Newtons (N). To convert this to kilograms (kg), we need to divide the weight by the acceleration due to gravity (g), which is approximately 9.81 m/s 2.

- Weight (kg) = Weight (N) / Acceleration due to gravity (m/s 2)

- Weight (kg) = 325 N / 9.81 m/s 2

- Weight (kg) ≈ 33.15 kg

Therefore, the weight of the bag of cement is approximately 33.15 kilograms.

Mass of Cement

The mass of the cement is a measure of its quantity, independent of the gravitational force acting on it. To calculate the mass of the cement in the bag, we can use the following formula:

Mass (kg) = Weight (kg) / Acceleration due to gravity (m/s2)

Substituting the values we have:

- Mass (kg) = 33.15 kg / 9.81 m/s 2

- Mass (kg) ≈ 3.38 kg

Therefore, the mass of the cement in the bag is approximately 3.38 kilograms.

Applications of Cement

Cement is a crucial construction material, widely used in various applications across the industry. It is the primary binder in concrete, mortar, and other composite materials, providing strength, durability, and versatility.

Uses in Construction, A bag of cement weighing 325 n

- Concrete Structures:Foundations, columns, beams, slabs, and walls of buildings, bridges, and other structures.

- Masonry Mortars:Binding bricks, blocks, and stones in walls, fences, and pavements.

- Plaster and Stucco:Providing a smooth, protective surface on interior and exterior walls.

- Grout:Filling gaps and joints between tiles, stones, and other materials.

- Road Construction:As a base layer for asphalt roads and highways.

Uses in Other Industries

- Precast Concrete Products:Blocks, pavers, pipes, and other pre-molded components.

- Agricultural Applications:Stabilizing soil, constructing silos, and lining irrigation canals.

- Mining:Reinforcing mine shafts and tunnels.

- Water Treatment:Constructing reservoirs, dams, and water purification systems.

Advantages and Disadvantages of Cement

Advantages:

- High strength and durability

- Versatile and adaptable to various applications

- Fire-resistant and weather-resistant

- Cost-effective in large-scale projects

Disadvantages:

- Requires skilled labor for proper handling and application

- Can be brittle and prone to cracking if not reinforced properly

- Production can contribute to greenhouse gas emissions

- May require additional materials, such as steel or fibers, for reinforcement

Manufacturing Process of Cement: A Bag Of Cement Weighing 325 N

The manufacturing process of cement involves several stages, from quarrying raw materials to grinding and packaging the final product. The chemical reactions that occur during cement production are complex and involve the formation of various compounds.

Quarrying and Crushing

The first step in cement manufacturing is quarrying limestone, clay, and other raw materials. These materials are then crushed into smaller pieces to facilitate further processing.

Grinding and Blending

The crushed raw materials are then ground into a fine powder. This powder is blended with other additives, such as gypsum, to adjust the properties of the final cement.

A bag of cement weighing 325 N is quite heavy. That’s more than twice the weight of an average person! Speaking of investments, tommie has made an investment that could potentially double his money. But back to the bag of cement, it would take a strong person to lift it.

Preheating

The blended powder is preheated in a kiln to remove moisture and other impurities. This preheating process prepares the powder for the next stage, where it undergoes a chemical reaction.

Clinker Formation

The preheated powder is fed into a kiln, where it undergoes a chemical reaction known as clinkerization. During this process, the powder melts and forms small, hard nodules called clinkers.

Grinding and Packaging

The clinkers are cooled and ground into a fine powder. This powder is then mixed with other additives, such as gypsum, to produce the final cement product. The cement is then packaged and stored for distribution.

Environmental Impact of Cement Production

Cement production, a vital process in construction, raises environmental concerns due to its significant carbon footprint and emission of harmful pollutants. Understanding these impacts and implementing sustainable practices are crucial for mitigating the industry’s environmental burden.

The primary environmental impact of cement production is the emission of greenhouse gases, particularly carbon dioxide (CO2). During the manufacturing process, limestone (CaCO3) is heated at high temperatures, releasing CO2 as a byproduct. This process accounts for approximately 5-8% of global industrial CO2 emissions.

Sustainable Practices in Cement Manufacturing

Recognizing the environmental challenges, the cement industry is actively exploring sustainable practices to reduce its carbon footprint. These measures include:

- Alternative fuels:Replacing fossil fuels with biomass, waste materials, and alternative energy sources reduces CO2 emissions.

- Process optimization:Enhancing energy efficiency and reducing clinker content in cement can significantly lower CO2 output.

- Carbon capture and storage (CCS):Capturing and storing CO2 emissions prevents their release into the atmosphere.

- Use of supplementary cementitious materials (SCMs):Incorporating materials like fly ash, slag, and silica fume reduces the need for clinker, thus reducing CO2 emissions.

- Energy-efficient equipment:Utilizing energy-efficient machinery and optimizing production processes further minimizes energy consumption.

Essential Questionnaire

What is the weight of a 325 N bag of cement in kilograms?

Approximately 33.1 kilograms

What are the common uses of cement?

Construction of buildings, bridges, roads, and other structures

What are the environmental concerns associated with cement production?

Greenhouse gas emissions, air pollution, and resource depletion